Community, Leadership, Experimentation, Diversity, & Education

Pittsburgh Arts, Regional Theatre, New Work, Producing, Copyright, Labor Unions,

New Products, Coping Skills, J-O-Bs...

Theatre industry news, University & School of Drama Announcements, plus occasional course support for

Carnegie Mellon School of Drama Faculty, Staff, Students, and Alumni.

CMU School of Drama

Thursday, March 07, 2024

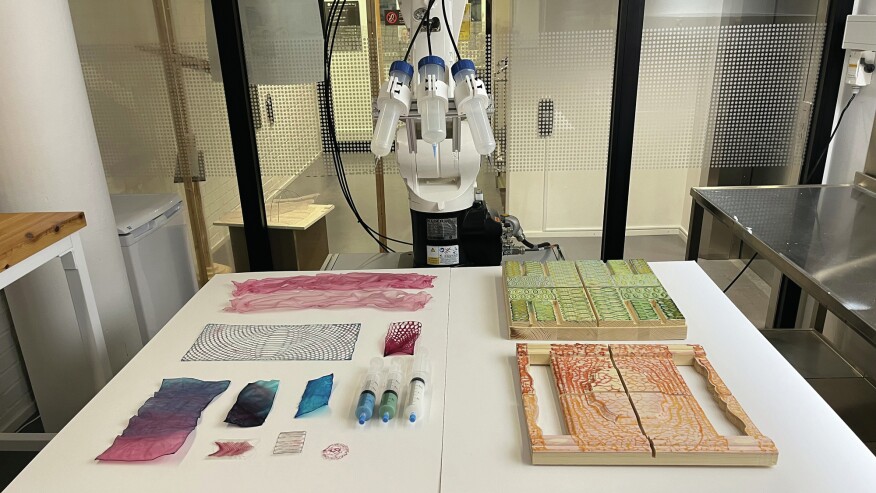

Revolutionizing Construction: The Rise of 3D-Printed Nanocellulose

Architect Magazine: 3D printing has been heralded as an environmentally advantageous method to make building products. One benefit is the potential material savings associated with reduced formwork or molds. Another is the energy savings in transportation and other distribution-related activities when products are fabricated on-site.

Subscribe to:

Post Comments (Atom)

4 comments:

The advancements in 3D printing technology as of late are truly amazing. I think it’s pretty awesome that there is so much development to using 3D printing as a method of creating a more sustainable construction industry. It’s nice to see that sort of care about improving sustainability, and even nicer to see that advancements have been made and positive results acquired. This article really covers preliminary research into two major sustainability improvements, one being the use of 3D printing and other being the concept of using nanocellulose. It’s pretty cool that nanocellulose (or Wood 2.0, which is what I’ve gathered it basically is) checks all of the boxes for epic sustainable material. I’m sure that Wood, But Better! currently costs an arm and a leg to use, but I hope that in the future I Can’t Believe It’s Not Wood! eventually becomes a relatively common building material and maybe we’ll be 3D printing sets with it. That’d be pretty cool.

Now this is an interesting invention in the 3D printing realm. I’ve read a decent chunk of articles and readings about 3D printing materials and how it could change the way certain industries work, and to hear of another innovation in the industry with a different type of material that might deliver on some of the hopes and promises that have been bouncing around for years is exciting. There are so many fascinating innovations in the article, but the idea of making architectural membranes with nanocellulose hydrogel (something which I think I will be rabbit-hole researching after posting this comment), really stuck out to me, as it seemed applicable to so many kinds of structures on a broader scale. Down the road, I’d be interested to see how this could become a useful and applicable technology for theatrical and more broadly entertainment construction shops. Materials like lauan are not particularly environmentally friendly, and if brought to a large enough scale and economic level in mass production, I think it would be cool for this to be one of the options that shops look at to lower their environmental impact overall. This is a technology I really look forward to following as it progresses.

I wonder about the recyclable capabilities of this product. A key tenet of a 3d printed future is the ability to take the molds and models that one creates with a printer, and to recycle the material either by melting it down or by high amounts of pressure, into more filament to be used for other projects. Could this product be melted down for use in more things, or potentially even composted into matter for plants to grow in. I'm also confused with regards to the operation of this specialized kind of printer. How does this technology actually work mechanically? It says it only uses compressed air, but how could that be used to produce a steady stream of material? I really hope that this prints from a vat akin to resin printing, as it is much better to carry around a liquid than a roll of filament. You can get way more bang for your buck if you can afford the slightly higher initial costs.

This is extremely intriguing to me. I am someone who believes that things should be handcrafted especially those things that are in our house every day. we should cherish the simple things around us like a kitchen island or a wooden spoon that we use to toss a salad. however, I am also one who believes sustainability is one of the most important things to keep in mind while moving forward in our future. in arts as well as everyday items. this article enlightened me on how 3D printing is truly revolutionizing the way we will most likely move forward. Nanocellulose is now able to be 3D printed which is making it sustainable to work with. it also rubs me the wrong way, something about an item being built of something artificial isn't right. Howeve, I guess we've done it to ourselves with pollution as well as not helping our world in climate change as well as global warming. the sheer destruction of humanity we have brought upon ourselves is now changing the way we will move forward.

Post a Comment