Community, Leadership, Experimentation, Diversity, & Education

Pittsburgh Arts, Regional Theatre, New Work, Producing, Copyright, Labor Unions,

New Products, Coping Skills, J-O-Bs...

Theatre industry news, University & School of Drama Announcements, plus occasional course support for

Carnegie Mellon School of Drama Faculty, Staff, Students, and Alumni.

CMU School of Drama

Wednesday, January 13, 2016

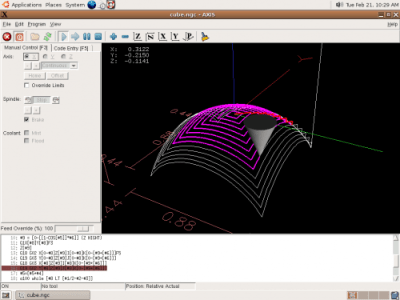

Sourcing your CNC Tools in 2016: Build Them

Hackaday: Perhaps the tolerances on today’s hobbyist machines just aren’t good enough for you, or perhaps the work area is just too cramped. Either way, there are times when an off-the-shelf solution just wont fit your needs, and you resolve to build your own CNC machine. Fortunately, none of us are alone in this endeavor because hobbyists have been building their own automation equipment for years.

Subscribe to:

Post Comments (Atom)

1 comment:

If you build your own CNC router by hand and then use it to make furniture, is that furniture hand made? I don’t really think so but it is super impressive to build a CNC. I have very limited CNC and 3D printer experience and most of that experience is just hitting GO so I do not totally understand G-Code or the motor control or a lot of the technology behind the actual process, so it may be simpler than I think or far more complicated, but either way I think it is cool that hobbyists are basically building their own robots. I do not think more accessibility to building your own CNC will hurt sales for large commercial or even high end CNCs, but I think if someone has enough passion to CNC but would only buy a small hobby machine they may opt to make their own instead for the challenge and to use it to make hand made furniture.

Post a Comment