Community, Leadership, Experimentation, Diversity, & Education

Pittsburgh Arts, Regional Theatre, New Work, Producing, Copyright, Labor Unions,

New Products, Coping Skills, J-O-Bs...

Theatre industry news, University & School of Drama Announcements, plus occasional course support for

Carnegie Mellon School of Drama Faculty, Staff, Students, and Alumni.

CMU School of Drama

Friday, August 31, 2018

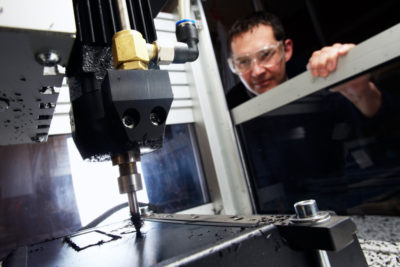

Speeds and Feeds for New CNC Machinists

Fusion 360 Blog: Feeds and speeds: they can make or break a job, and usually a tool or two. When dialed in properly, the right settings can lead to increased material removal rates, a surface finish that meets requirements without hand work, and increased tool longevity. So what’s the magic sauce to figure out your perfect feeds and speeds? Let us know if you find out.

Subscribe to:

Post Comments (Atom)

1 comment:

The topic of feeds and speeds has always been up for discussion. Normally when you ask a real machinist it is impossible to get an answer that is actually worth anything. If you go onto any machining site to find this information it usually doesn’t give you any advice or you get 20 different answers to the same question.

In my personal experience, the best way to calculate your feeds and speeds are by trying and listening to what the tool is doing. Every good machinist knows what sounds to listen and if you have a happy machine.

My problem with this article is how the author assumes everyone has a machine that can effectively function at the given values. For example, the Bridgeport mill that I am familiar with does not have the capability to function at the spindle speed specified, but that doesn’t necessarily mean it can’t perform the task. A better solution to this would be a library that updates based on a set of given parameters.

Post a Comment