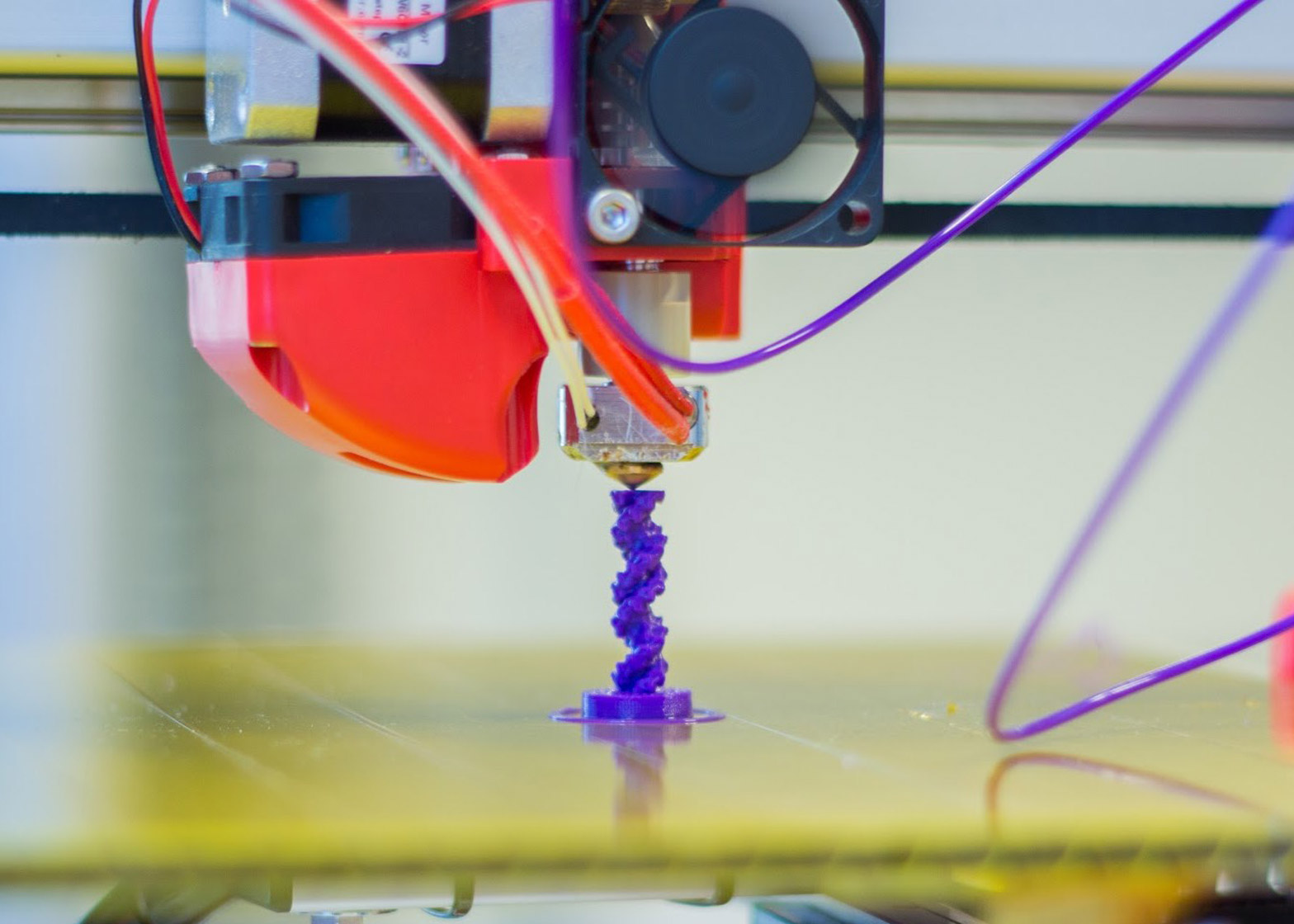

www.dezeen.com: A team of scientists has published a study that details the health hazards of 3D printing in enclosed spaces, which it says causes the release of toxic and carcinogenic particles.

The study – conducted by a group of scientists at the Illinois Institute of Technology – tested five major brands of 3D printers including the Makerbot Replicator 2X and LulzBot Mini.

2 comments:

I think this article has some good points, but it isn’t all that surprising. Melting anything can produce hazardous fumes. What does surprise me is the emission of particles. It sounds to me like not all of the filament extruded goes into the item being printed, some of it is emitted into the space around the printer. This problem seems like likely for our 3D printer since it is completely closed and contained, though fumes could still get out. Other, open-air models, seem to be the culprit for most of the concern surrounding 3D printers. It seems like the solution could be a fume collector, much like what is used for welding. I think that as 3D printers become more common, we will see new ways around these problems. For now, it seems that the best solution is just to use a 3D printer in a well ventilated area, make sure everyone knows the conditions under which it should be used, and don’t stick your head in a 3D printer.

This article is 100% correct when saying melting plastic releases toxic gases. That being said, I don’t think this is something that was discovered because of 3-D printers. These scientists must have missed the family camping trips where your dad tells you never to put the bottle caps in the fire. I am a student at CMU and it is university rule that all 3-D printers be in a properly ventilated room that can remove the hazardous gasses emitted from melting plastic. In my experience I have seen the prints themselves enclosed and equipped with on board filtration systems that handle the gases.

If you are in the market for making your own 3-D printer, which I recommend you do, you are just going to have to improvise and set up a make shift ventilation system. What I found to be very successful is solder vacuums that sucks solder fumes away from your workstation. This is obviously t not a perfect solution but when you are in a pinch it will do the trick.

Post a Comment